Ukrainian passenger car today and in the future – decisions are to be taken

26.07.2023

Ukrainian passenger car today and in the future – decisions are to be taken

Experience opens up opportunities

Recently, an interview of “NV Business” correspondent Artem Ilyin with the new chairman of the board of JSC “Ukrzaliznytsia” Yevhen Lyashchenko was published. I read it with great interest. It is gratifying that it involves issues important not only for the railway, but also for the whole Ukraine, namely – modern passenger cars of Ukrainian domestic production. Obviously, we, as the railway car builders are most interested and worried about this.

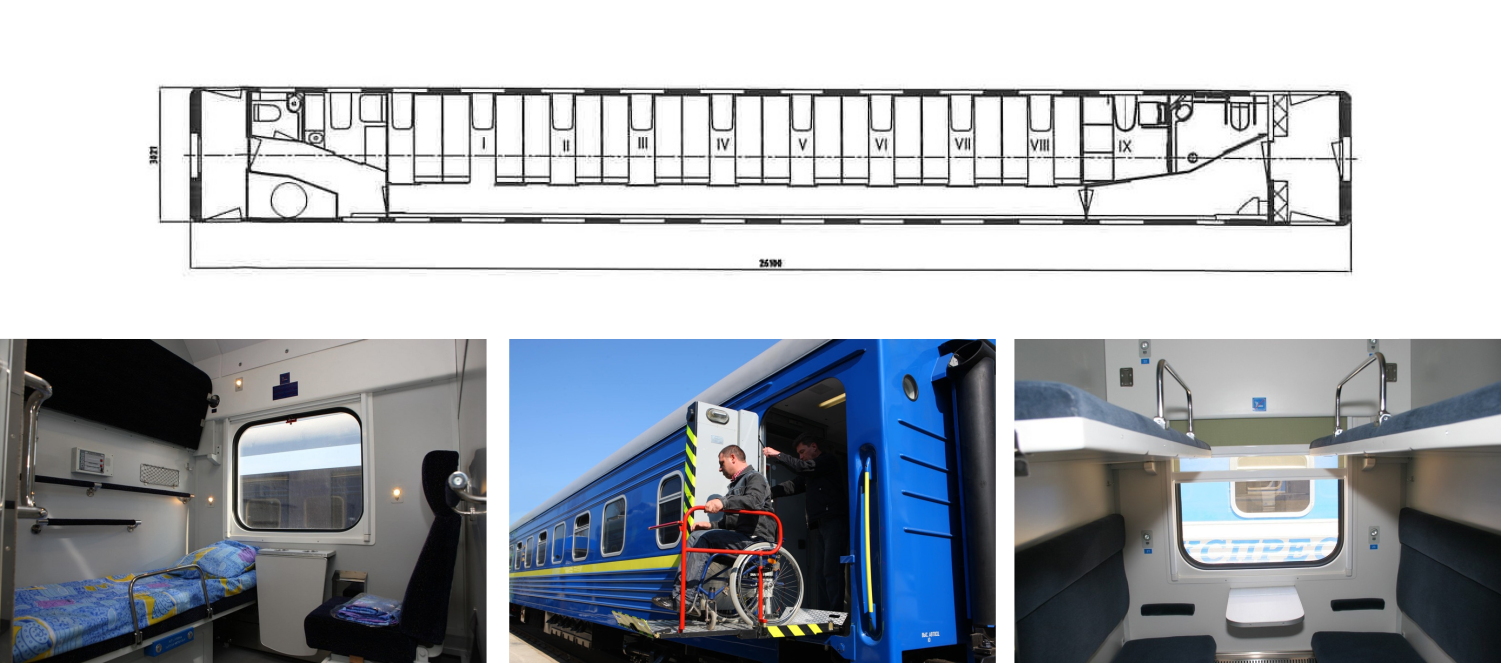

After the interview, Yevhen Lyashchenko and the head of the passenger company Oleksandr Pertsovsky showed Artem Ilyin the car manufactured at the 2023 by KRCBW. The journalist’s attention was drawn to numerous changes. “Special attention, he writes, should be paid to the compartment for passengers with disabilities, where a place for a wheelchair is provided, as well as the ramp for convenient access to the car.”

I would like to add: the car of this model is also provided with a bathroom with space for the wheelchair and all other arrangements for convenient usage. As for air conditioners and vacuum toilets, they have become an integral part of the design of all passenger cars and trains produced by Kryukovsky Railway Car Building Works, starting with the very first car assembled in 2001 for the anniversary of Ukraine’s Independence.

22 years have passed since that time. During that time the new branch of passenger car construction has passed a path of constant development and improvement. We have always tried to meet modern trends in the field of rail transport, the challenges of time, the needs of passengers and the requirements of the operating company. Obviously, we succeeded to a large extent.

The most recent example is the project of assembling and supplying 100 passenger cars for budget funds. This state order was presented by the President of Ukraine Volodymyr Zelenskyi in 2020 during his stay at PJSC KRCBW. During the years of Ukraine’s independence, this is the first event when the state invested in passenger rolling stock.

It just happened that the cars from this order became the basis of the great humanitarian mission of Ukrzaliznytsia, a symbol of the salvation of millions of Ukrainians, as the cars were leaving the factory already for evacuation routs. Important foreign guests and partners traveled around Ukraine in these cars. Dmytro Komarov filmed his interview with Volodymyr Zelensky for the film “The Year” in our car.

But these are not the only peculiarities of this project. It is important that these passenger cars were the product of an exclusively domestic school of passenger car construction. More than 85% of the project was implemented by the forces of Ukrainians in conditions of unprecedented military aggression. The product was created with the maximum involvement of components of domestic production with the participation of about 160 neighboring enterprises, jobs were saved, budgets of all levels received additional income. We have gained experience that opens up opportunities to create a new generation of passenger cars in the future together with the Ukrainian Railways.

Formation of the domestic passenger car platform

From the first years of Ukrainian independence, the shortage of passenger railway rolling stock became noticeable. It was decided to create its own branch of passenger car construction. We had to move step by step: the concept, design and technological solutions, the first samples and their tests, the construction of production facilities, the involvement of partner enterprises, scientific organizations, learning from the experience of leading European manufacturers, etc.

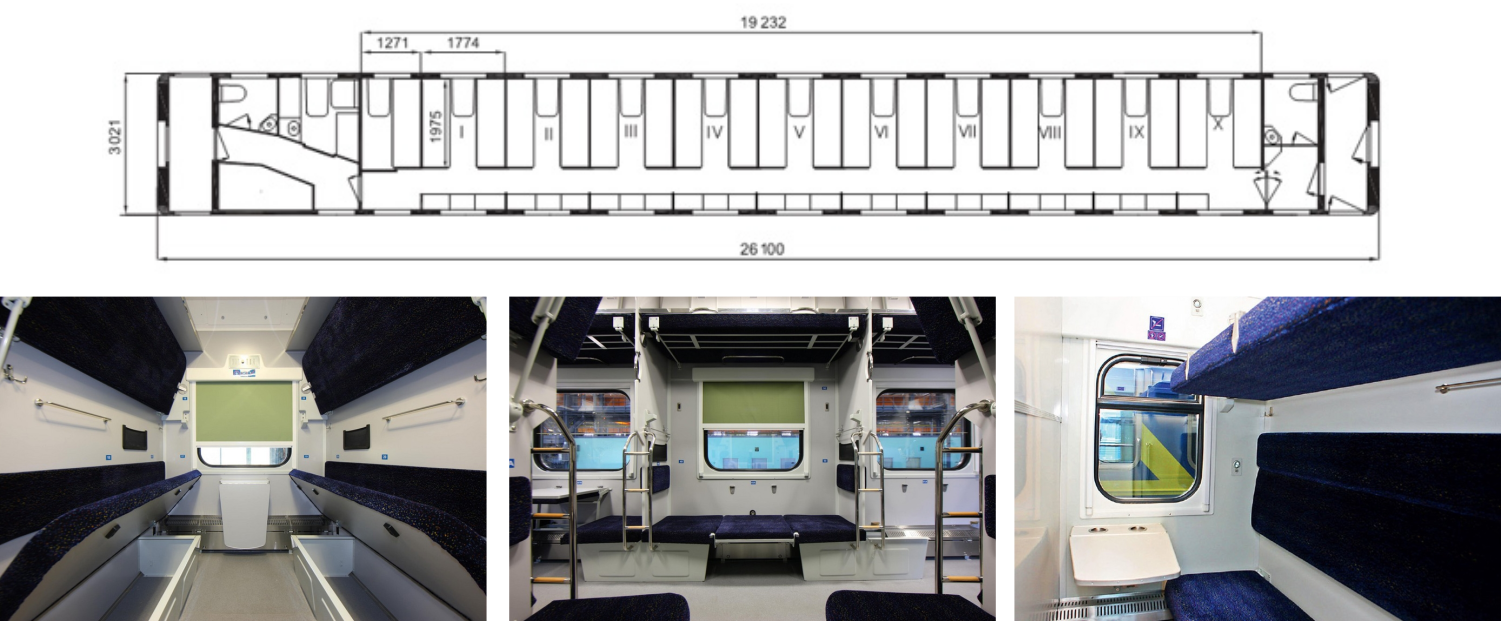

Already at the beginning of 1993, at a broadened meeting of the Scientific and Technical Council of Ukrzaliznytsia, the basic technical requirements for the development of a passenger car for Ukraine were considered. At the same time, its main parameters were determined – the length of the body is 26.6 m and the base is 19 m, 10 compartments and 40 seats in a car. Such parameters provided increased passenger capacity and potential for further modernization.

The cars that were serially produced in the CIS countries have 9 compartments and 36 seats. That is, a 9-car train of KRCBW (each car has 40 seats) carries 360 passengers. For the same number of passengers, 10 cars of classic design will be required. Other manufacturers of the CIS countries managed to increase the length of the car to 25.5 m only in 2008.

The KRCBW passenger car provides savings in electricity, fuel, costs for conductors and maintenance of the car fleet in operational condition. On national basis these are significant funds that can be directed to the timely and rhythmic renewal of the rolling stock.

Please, pay attention to the table showing the ratio of the main parameters of passenger cars of various manufacturers.

Basic technical characteristics of passenger cars of various manufacturers

| Parameters | «47К» «НДР», «СРСР» | «61-779» «КВБЗ» | «61-4440» «ТВЗ» | «61-4517» «ТВЗ» | «Nightjet» «QBB» |

|---|---|---|---|---|---|

| Start of production, year | 1951 | 2004 | 2008 | 2021 | 2021 |

| Gauge, mm | 1520 | 1520 | 1520 | 1520 | 1435 |

| Equipment diagram | 1-ВМ | 1-ВМ | 1-ВМ | 1-ВМ | RIC |

| Length over pulling faces of couplers, mm | 24540 | 26696 | 25500 | 25500 | 26500 |

| Length over the car body, mm | 23954 | 26100 | 24924 | 24924 | 26100 |

| Car width, mm | 3100 | 3021 | 3104 | 3104 | 2825 |

| Wheelbase, mm | 17000 | 19000 | 17000 | 17000 | 19000 |

| Number of passenger compartments | 9 | 10 | 9 | 9 | 12 |

| Number of passenger seats | 36 | 40 | 36 | 36 | 36 |

As you can see, from the very beginning serial cars produced in Ukraine were focused exclusively on the European experience (length and base of the car) of car construction with organic integration of the possibilities provided by the 1520 mm track gauge.

In the period from 1994 to 2000, Ukrainian enterprises developed, tested and recommended for production the main components for the production of a domestic passenger car (converter, air conditioner, distribution cabinet, generator, etc.). Such car was created, as I already mentioned, in 2001, and serial production of the car started the following year.

Ukraine managed to create a complex science-intensive product in the shortest possible time, which even now is produced by a limited number of manufacturers in the world.

For its time, this car had a modern interior and an innovative concept for the 1520 mm gauge, which none of the manufacturers in the post-Soviet space had at that time. It was the first car of the 61-779 model. KRCBW supplied it to Ukrzaliznytsia in various configurations and exported it to Belarus, Kazakhstan and Tajikistan. Each batch of cars had its own characteristics and was distinguished not only by the interior, which certainly catches the eye of passengers the most, but also by the constant modernization of the car’s internal systems.

The 779 series has become a truly popular product for the domestic market. So far, 751 units have been produced, and a total of 17 models and 23 modifications of this series have been created. During the period of production from 2002 to 2023, the serial passenger cars were modernized and structurally changed. First of all, they were aimed at increasing the level of passenger comfort and minimizing service costs, based on the gained experience in the operation of carriages and joint work directly with the passenger transportation operator.

Complex modifications were implemented not only for individual components, but also for the basic systems of the cars. These are, in particular, anti-corrosion measures that made it possible to increase the reliability of vestibule elements and external doors (starting from doors made of ordinary structural steel and to stainless steel doors with the subsequent transition to aluminum). As a result – a reduction of repairs amount.

The designers managed to reduce the weight of the cars despite the constant equipping of them with additional electrical equipment (sockets for each passenger, cooler, coffee machine).

The optimization of the microclimate parameters in the car is constantly ongoing, which allows them to operate successfully in extreme climatic conditions (from -40 to +50° C) while providing comfortable conditions for passengers.

The efficiency of the braking system has also increased, the smoothness of movement has increased due to the use of modern bogies and the optimization of the parameters of the car suspension system.

The complex control system of the car was modernized in order to increase its energy efficiency and level of automation.

A change-over to a modern bolsterless bogie with disc brakes was made, which, according to its basic technical solutions, can provide movement at speeds up to 200 km/h.

All this was implemented simultaneously with constant and systematic work on improving the interior, creating various lay-out solutions, work areas, configuration and equipment of individual rooms of cars. Constant attention in this segment is paid to the introduction of modern elements that are used directly by the passenger: USB sockets, stands for gadgets, various tables, ergonomic handrails and armrests, cup holders, etc.

Separately, it is worth mentioning the manufacture at KRCBW of its own running components – a series of domestic bogies. We have made our way from a bogie mod. KWZ-CNII for a serial passenger car to running parts of a high-speed two-system electric train (200 km/h and more). The first domestic undercarriages were based on Y-32 model bogies (De Dietrich, France). During 2001-2007, design documentation was developed, experimental batches were produced, and a full set of acceptance tests (including operational tests) was conducted, with permission for serial production of bogies of models 68-7007 and 68-7012 being obtained. At the same time, from 2005 to 2008, work was carried out on serial production of model 68-7013 bogies with an undercarriage generator drive from the middle part of the wheelset axle.

A new line of prospective series

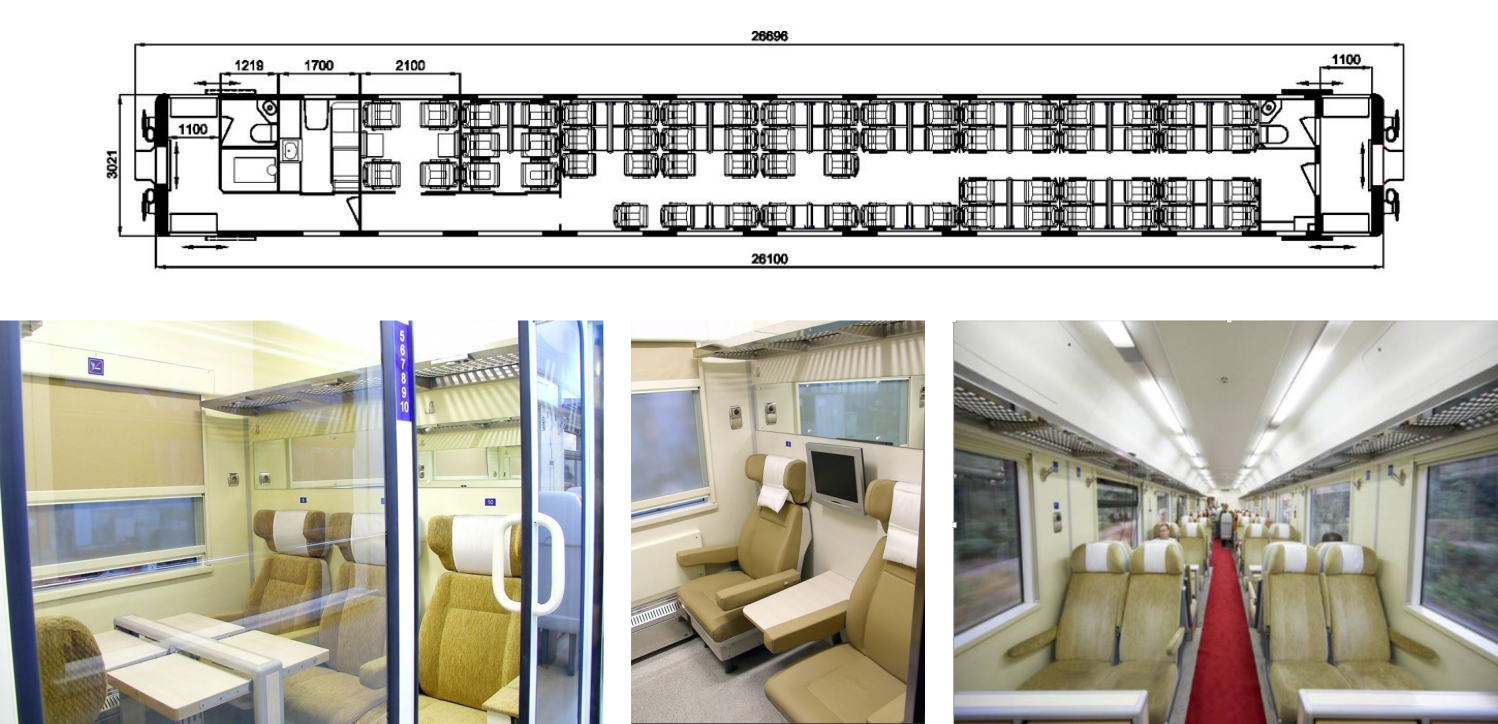

Domestic rail way car building companies focused on the development of more than one series of cars. At the same time, in 2004-2006, a new line of passenger cars of the improved 61-788 series was developed. A combined open-type car with seats with separate zones for 2nd and 1st class passengers and with the compartment for VIP passengers was the first to produce (Picture 6).

This model first featured an undercarriage static converter, sliding plug doors, smooth siding, bonded windows, electric boiler, diesel backup heating, disc brake bogies, and more.

At that time, Ukrzaliznytsia was considering the possibility of forming day trains from cars of this model, which as a result made it possible to have an optimal number of passenger seats of different levels of comfort in the train. On the basis of the 788 series cars, compartment and sleeping cars were created with passenger compartments of enhanced comfort and independent climate control for each compartment (Figure 7).

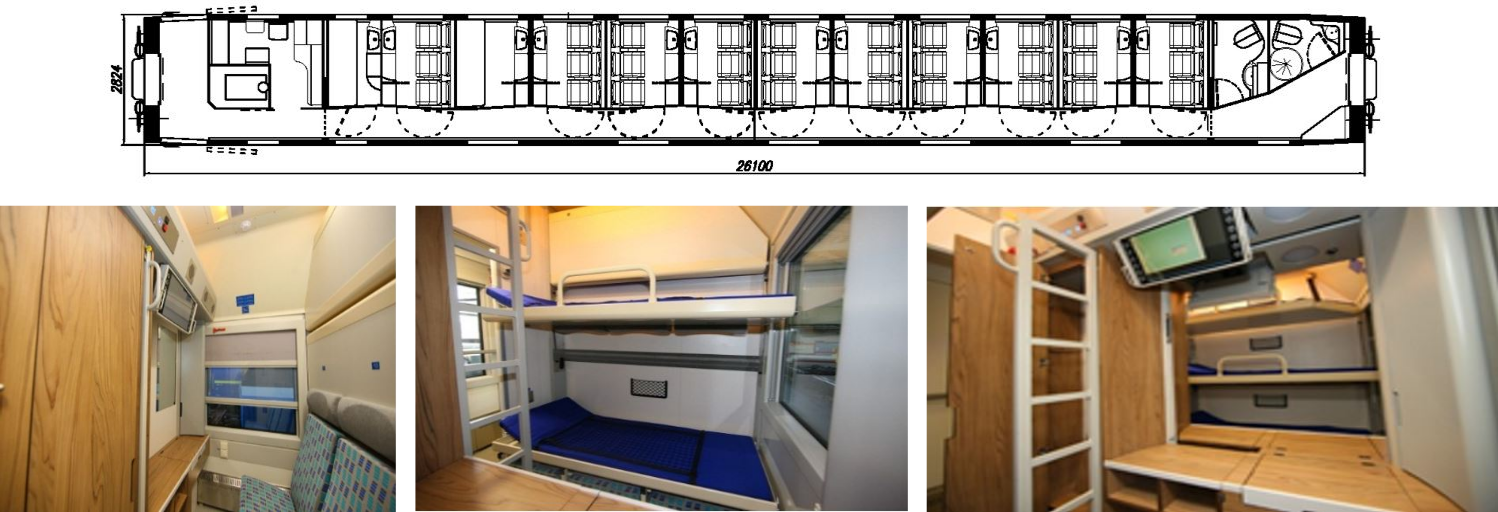

These cars were first steps before the change over to a fundamentally new type of passenger cars of “T” equipment diagram (Picture 8). Due to this innovation, it became possible not only to maintain the length of the car of 26.7 m, but also to increase the body to 3420 mm. The increased size of the passenger compartment allowed the designers to create various open-type interiors, and to offer the Ukrzaliznytsia several concepts of such cars, in particular for the formation of night trains. Along with this, bogies with central pneumatic suspension model 68-7041 were installed in these cars.

The design of the bogie mod. 68-7041 was created using the results obtained during the creation of model 68-7007 passenger bogies. At the same time, the design of the bogie was simplified, and its manufacturability was significantly improved. The main feature of this bogie was the applying of pneumatic springs produced by the German company Contitech Railway Engineering in the central suspension. The required control equipment of the pneumatic suspension system was supplied by the German company KNORR-BREMSE.

The running qualities of the new bogies, demonstrated by them during the tests, were significantly higher compared to the bogies mod. 68-7007 and exceeded the running qualities of the “KVZ-TsNII-M” type bogiess. Thus, the smoothness coefficient did not exceed 2.0 by a permissible coefficient 3.25.

Cars of the 788 series (carbody width 3021) became the basis not only for MPLT cars (start of operation in 2012), but also for high-speed electric train cars EKr1 (start of operation in 2013), and later for cars of diesel trains of the DPKr-2 series (start of operation in 2014) and DPKr-3 (start of operation in 2019).

All the specified rolling stock was created taking into account the climatic and infrastructural features of the Ukrainian railway. This approach of the domestic car builders made it possible to ensure stable and efficient operation, as opposed to the infamous HRCS2 imported electric trains (known as “Hundai Rotem”), in which fatigue cracks were detected on the load-bearing body metal structures already at the beginning of operation (2014). The emergency elimination of the detected cracks required suspension of each HRCS2 electric train for a period of 4 to 6 months.

Simultaneously with the creation of “T” cars, the production of RIC cars (Picture 9) with the possibility of movement on both 1520 mm and 1435 mm track gauge was mastered. The manufactured samples have successfully passed tests both in Ukraine and abroad, the necessary permits have been obtained. Unfortunately, out of 50 wagons declared for purchase by Ukrzaliznytsia in 2020, only 2 were purchased. Unfortunately, only 2 cars were purchased by Ukrzaliznytsia out of 50 declared for purchase.

It is worth noting that the discussions about these cars have not subsided to this day. Recently, information appeared on the official Telegram channel of UZ and on the “News-Live” internet resource about the features of cars for international traffic, using the example of RIC cars. They say that cars “cost a fortune”, and their production takes several years. That’s a stretch and untrue!

Yes, sirs, a car for international traffic is more complicated from a technical point of view. It is designed for a speed of 200 km/h, contains redundant systems to move on different track widths, in different infrastructure conditions and interact with domestic and European traction rolling stock. It meets the security requirements valid both in the EU as a whole, and in each country.

All this requires the application of a complex multi-level control system, a double braking system, special auto-coupling devices, sliding-plug doors local and centralized control, the use of a power supply system capable of working with different types of current, etc. Besides, the delivery set includes two pairs of bogies – for a track of 1435 and 1520 mm.

t is not easy to produce such car: you need more materials, components, and therefore more time. Of course, it will be more expensive than classic rolling stock. The production time and cost are determined by the specifics of the equipment and the customer’s requirements. The assembly of the RIC car currently takes 16-18 months, followed by the receipt of a package of permit documents. For railway equipment of this level, this is more than acceptable.

Instead, we get the opportunity to transport passengers to Warsaw, Vienna, Budapest, etc. Taking into account the course of our country towards European markets, the increase in the fleet of RIC cars can be considered as one of the vectors of the development of Ukrainian railways.

The practice of international passenger transportation, the increase in the flow of passengers in the European direction confirms that new modern domestically produced RIC cars were required by UZ yesterday. And we have the opportunity to manufacture and service them in Ukraine. It’s time to make a decision!

The comfort of passengers is our priority

Confirmation of the correctness of the chosen way of development of the concept of the Ukrainian passenger car is that in October 2020, the Tver Railay Car Building Works (TVZ) presented for public viewing and discussion a full-size mock-up of a passenger car with reserved seats, which was described as a promising platform for an entire family of cars. Its length over pulling faces of couplers is 26.7 meters, its width is 3380 mm, ten rooms, which can be equipped as compartments or reserved seats. These technical characteristics only repeat, but in no way surpass the ideas of Ukrainian car builders, implemented more than ten years ago. Key companies of the CIS countries plan to master the production of such cars only in 2024-2025.

An interesting fact is that it took more than 75 years for the manufacturers of the USSR, and then of the CIS, to go from the start of production in 1951 at the Kalinin Railway Car Building Works (now TVZ) of the passenger car, which for many years became the basis for the 1520 mm track gauge to creation of only a mock-up of a “T” passenger car. For Ukrainian railway car building companies it took 6 years to go from creating their first car in 2004 to creating a mock-up of “T” passenger car in 2009, and put two five-car trains into operation in 2012.

That is, in just 8 years, Ukraine has gone through a journey of 75 years, putting the product into production, and not limiting itself to the demonstration of exhibition samples. The product was put into production, not limited to the demonstration of exhibition samples This was done due to creativity and the desire to use the most advanced and promising achievements of the leading car-building countries of the world, putting the maximum focus on passenger comfort.

All the work carried out by domestic railway car building companies and the most successful solutions and inclusive technologies obtained during this time were implemented for the project to supply 100 passenger cars in accordance with the contract signed between JSC “UZ” and PJSC “KRCBW”. PJSC “KRCBW” manufactured and delivered:

- 51-passenger compartment sleeping car model 61-779;

- 12 compartment sleeping cars model 61-779A;

- 20 inclusive compartment sleeping cars model 61-779EGI equipped for transportation of passengers with disabilities in wheelchairs;

- 17 passenger compartment sleeping cars model 61-779EGY, equipped for the transportation of passengers with disabilities in wheelchairs and the train master’s compartment.

The specified model range of passenger cars (61-779, 61-779А, 61-779EGI) is a modern and innovative rolling stock, which favorably differs from the existing rolling stock that has been in operation on the Ukrainian railway for a long time.

In particular, modern ergonomic solutions are implemented in the design of the cars, which ensure the provision of a qualitatively different level of passenger transportation service. The design of the cars fully meets the requirements of sanitary standards for ergonomics, microclimate, lighting, noise and vibrations, and safety requirements.

The interior of the cars has a modern design, made of plastic and metal panels using wear-resistant, environmentally friendly, flame-retardant materials.

Sometimes passengers pay attention to the fact that these cars still have an electric coal-fired boiler and bogies without central pneumatic suspension. But such an approach is determined by technical and economic expediency. The use of an electric coal-fired boiler makes it possible to provide autonomous heating of the car in the event of its inactivity on the route without access to electricity. And the benefit of this was proven in the 2022 war year, which does not require additional explanations.

The pneumatic suspension will require deep modernization of all trains and will exclude the possibility of voluntary combination of cars during the formation of trains, which is unacceptable during operation.

During the implementation of 100-cars-project, special attention was paid to the creation of car mod. 61-779EGI (Picture 10), adapted for the transportation of people with limited physical abilities in wheelchairs and their accompanying persons. This car was created in close cooperation not only with JSC “UZ”, but also with the National Assembly of People with Disabilities of Ukraine.

The design of the car takes into account and implements all wishes regarding the accessibility of the car for passengers with disabilities and other groups of the population with reduced mobility. Compared to the cars that were produced before, the dimensions and layout of the compartment and toilet for people with disabilities were completely changed. All furniture and equipment in this car is arranged in such a way as to ensure the maximum comfort of passengers during their trip and the availability of using the all the equipment. For people with poor sight bright color solutions are used in the interior design – the entrance, door rails are highlighted in color, bright colors are used on the information boards, the light control panels are located at an accessible height in each compartment, all inscriptions are duplicated in Braille. A retractable ramp is used in the design of the car for the convenience of boarding passengers with disabilities.

Analyzing the way we passed, it is not difficult to conclude that in the competition between two engineering and design schools of creation new passenger cars, in our opinion, the Ukrainian one is the most challenging, creative and innovative. And this is not a subjective assessment, since it is based on the fact that for a long period of time, Ukrainian railway car builders were one step ahead, not in matters of the features of passenger furniture, but in relation to the conceptual change of passenger rolling stock, aimed at achieving maximum comfort, ergonomics and effective transport economy.

Glimpse into the future

Currently, the 779 series cars have not lost their relevance at all and have the potential for further development and modernization. PJSC “KRCBW” and other manufacturers of rolling stock understand that only constant development and the search for new solutions will ensure sustainable development of the industry.

Right now, Ukrainian railway car building companies are at the beginning of forming a concept for the further development of passenger railway car building. It is clear that currently the main struggle will be between the concepts of comfort, inclusiveness and economic expediency.

These are competing concepts in the field of railway passenger transportation, since increasing comfort and creating an open, accessible environment often requires an increase in the useful area per passenger and the installation of additional equipment, and therefore leads to a decrease in the profitability of transportation at an external value. Finding the optimal ratio requires bold decisions based on experience and the latest trends.

Railway car building companies, together with railway passenger servicing companies are in constant close dialogue to find the optimal ratio of these parameters. From our point of view, further development will be focused on three directions:

- Further improvement of cars of the 779 series in terms of their openness for use by passengers with limited physical capabilities due to the wide implementation of inclusive technologies.

- Creation of “1-T” car (width 3200 mm). They will be able to function in one formation with classic “1-VM” cars both on electrified and non-electrified sections of the route. At the same time, a much higher level of comfort for passengers will be ensured and a number of promising technologies for this type of rolling stock will be introduced – smooth siding, bonded windows, etc.

- Creation of a new line of passenger cars based on the “T” car platform (width 3420 mm). These cars will be able to run on electrified sections of the route because of the absence of a generator under the car. In this case, one conceptual question remains: one or two vestibules? The variant with one vestibule was implemented in European countries at different times (CNL, ÖBB).

All these directions are already being actively developed not only within the framework of a separate enterprise, but discussions are held in specialized departments of the University of Technology, scientific institutions and directly with users. It should be understood that the creation of technology of such complexity in a short period of time is possible only with the efforts of the entire country with a clearly formed state position and is an indicator of the society development level as a whole.

Systematic approach to updating rolling stock

The Ukrainian school of passenger car construction is based on the European experience of creating rolling stock, taking into account the opportunities provided by the infrastructural features of the Ukrainian railway (track 1520 / 1435 mm).

During more than 20 years of the domestic car history, it went long way of modernization, which made it possible to create a product that harmoniously combines comfort, inclusiveness and economic efficiency.

Since the independence of Ukraine, Ukrainian railway car builders have created a whole line of various passenger rolling stocks, which fully meets the needs of the passenger transportation operator.

Recently, some experts have formed the opinion that domestic passenger railway car construction has lagged far behind advanced trends in the field of providing comfortable and cost-effective passenger transportation. Such conclusions are usually made only on the basis of a subjective assessment of interior elements. My story refutes this opinion and once again convincingly proves that Ukrainian passenger cars meet modern requirements and are quite competitive not only on the domestic market, but also on the European market (RIC gauge cars). The existing serial solutions, which are already widely used today in Ukrainian passenger cars, are nothing but the future for the CIS countries.

A modern Ukrainian passenger car is the optimal transport for the organization of economically profitable transportation with minimal cost not only for the purchase of rolling stock, but also for providing its service. At the same time, at the request of the customer, various interior solutions can be used in the design of the car.

The trends in the modern development of passenger cars allow not only to confirm the correctness of the technical solutions chosen by domestic railway car builders, but also to confirm the correctness of the selected perspective concepts for further development (“T” cars, 19 m base, one vestibule, etc.).

The domestic railway car building industry is waiting for a clear signal from Ukrzaliznytsia, as the national operator of passenger transportation, regarding the definition of technical requirements for promising domestic cars, including RIC cars. The issue of updating the rolling stock should be based on a systematic approach, designed in the form of a program for the purchase of cars with a clear definition of quantities and deadlines of implementation. Only in this case is it possible to create a competitive and optimal product from the point of view of combining technical solutions and economic feasibility by mobilizing the joint efforts of industrial enterprises, scientific institutions and the operator of passenger transportation. Any delay can lead to irreversible changes and lagging domestic railway car construction behind other countries, and it will be almost impossible to make up for lost time under current conditions.

Volodymyr PRYKHODKO,

Chairman of the Supervisory Board – President of PJSC “Kryukovsky Railway Car Building Works”, Member of the presidium of the Federation of Employers of Ukraine, Laureate of the State Prize of Ukraine in the field of science and technology, Candidate of Technical Sciences.

Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit