Starline High-Speed Rail Boosts Europe’s Manufacturing Future

03.04.2025

Starline High-Speed Rail Set to Transform European Manufacturing. This is reported by the railway transport news portal Railway Supply.

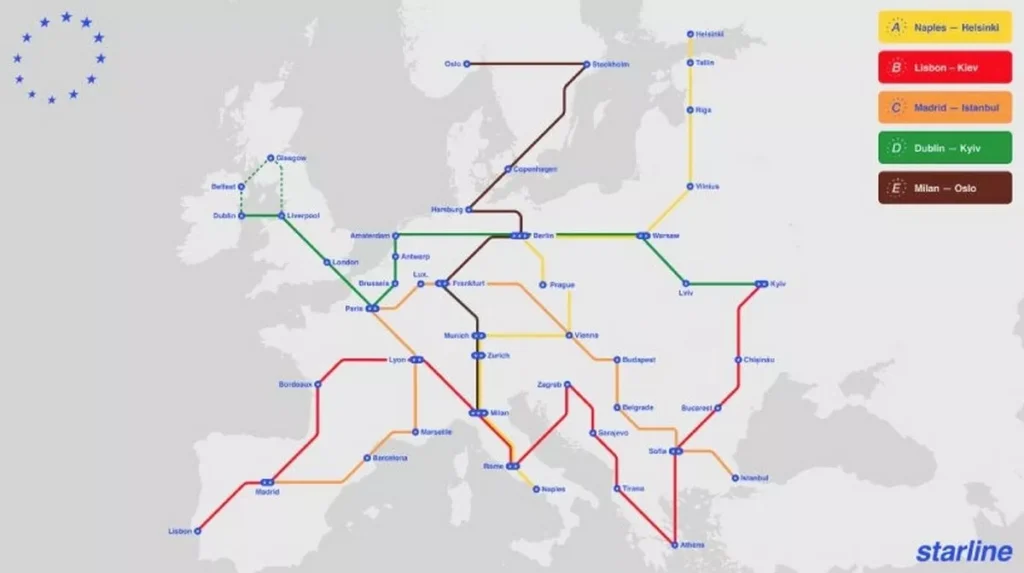

Europe’s Starline high-speed rail project promises faster travel and efficient freight logistics for manufacturers. This network aims to enhance supply chains across the continent swiftly.

Starline High-Speed Rail Enhances Freight Efficiency

Rail freight outperforms road transport by being four times more energy-efficient, yet only 18% of European goods travel by rail. For manufacturers needing timely deliveries, this rail system cuts reliance on congested roads and short-haul flights.

Don’t miss…For Sale: M62 and 2M62 Diesel Locomotives

The current rail network struggles with fragmented infrastructure and border delays, slowing down production schedules. Dedicated freight corridors enable goods to travel at 300–400 km/h, improving delivery speed.

Streamlining Industrial Logistics

Freight corridors ensure critical components reach factories quickly, enhancing just-in-time manufacturing reliability. Moreover, this shift reduces road congestion and carbon emissions, aligning with Europe’s climate objectives.

Manufacturers benefit from predictable delivery schedules, and businesses gain access to new markets without road dependency. Thus, this rail network strengthens industrial logistics while supporting sustainable growth across the region.

Overcoming Cross-Border Challenges

Fragmented rail networks across Europe create inefficiencies, despite the Schengen Agreement easing border controls. A unified high-speed system allows seamless cargo movement without logistical hiccups.

Real-time tracking provides manufacturers with precise updates on shipments, and automated scheduling prevents delays. As a result, factories, suppliers, and retailers connect more effectively, boosting Europe’s manufacturing sector.

Starline High-Speed Rail Transforms Stations

This rail project reimagines train stations as integrated logistics hubs handling both passengers and freight efficiently. These hubs streamline transfers between rail, road, and air, eliminating scattered distribution challenges.

Businesses cut logistics costs by reducing reliance on short-haul flights, and manufacturers receive materials faster. Additionally, this approach supports the EU’s net-zero goals by lowering transport emissions significantly.

Cutting Emissions and Costs

Transport generates nearly 30% of EU greenhouse gas emissions, with aviation growing rapidly. Shifting freight to high-speed rail helps manufacturers reduce their carbon footprint effectively.

This transition enhances supply chain sustainability, and it aligns with Europe’s 2050 net-zero ambitions. Therefore, this network offers a dual benefit of efficiency and environmental responsibility for industries.

Facing Infrastructure Challenges

Building this rail system requires substantial investment, and unifying national networks poses coordination difficulties. However, a proposed franchise model suggests operators manage routes under a European Rail Authority.

This authority sets technical standards and safety rules, ensuring consistent operations across borders. So, the project aims to overcome obstacles with a structured, collaborative approach to implementation.

A Vision Beyond Existing Plans

The EU’s TEN-T initiative seeks better connectivity, but backers demand greater ambition for freight. They argue that high-speed rail must drive modern manufacturing logistics forward.

Stations become commerce gateways, and freight moves without delays from outdated systems. Consequently, this vision positions Europe as a leader in efficient, sustainable industrial transport.

Boosting Manufacturing Competitiveness

Essential materials reach factories swiftly, enabling smoother production and lower operational costs with this rail system. Retailers restock efficiently, and businesses expand market reach without road transport reliance.

The Starline high-speed rail strengthens Europe’s manufacturing edge, fostering economic growth and resilience. Ultimately, it delivers a transformative solution for industry and sustainability combined.

Looking Ahead to a Connected Future

Success hinges on overcoming funding and coordination hurdles, yet the potential remains vast for this project. Manufacturers gain a competitive advantage, and Europe moves closer to its climate targets.

Factories operate more efficiently with seamless freight delivery, and supply chains become faster and greener. Thus, this rail network paves the way for a connected, sustainable European manufacturing landscape.

Source: manufacturingdigital.com

News on railway transport, industry, and railway technologies from Railway Supply that you might have missed:

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit