Robotics in the railway industry: TechInn s.r.o. at InnoTrans 2024

23.09.2024

TechInn s.r.o., founded in 2021 by Kirill Kasaev in Pilsen, Czech Republic, is rapidly capturing the market with its innovations in digital transformation of transport.

The company’s main focus is on creating advanced solutions for optimizing the maintenance and repair of transport systems, enhancing efficiency and safety in both railway and public transport.

Ahead of InnoTrans 2024, we decided to learn more about the driving force behind TechInn s.r.o.’s success and what innovations the company will showcase at the upcoming event.

Kirill Kasaev shares his thoughts on current achievements, future plans, and the importance of digital technologies in the transport industry.

– Kirill, your company TechInn s.r.o. was founded in 2021 with the goal of accelerating digital transformation in transport. What are the main achievements you can highlight during this time?

– The main achievement of TechInn s.r.o. is the successful implementation of a number of innovative solutions in the digitization and automation of processes in the transport industry.

We have developed several products that have significantly improved the maintenance and repair process of transport systems. Our solutions, such as the TechHydraulic Platform, DBOX ONE, and HYDBOX, have already started to deliver real results, reducing downtime and extending the life of rolling stock.

– TechInn s.r.o. will showcase its products at InnoTrans 2024. What new products do you plan to demonstrate?

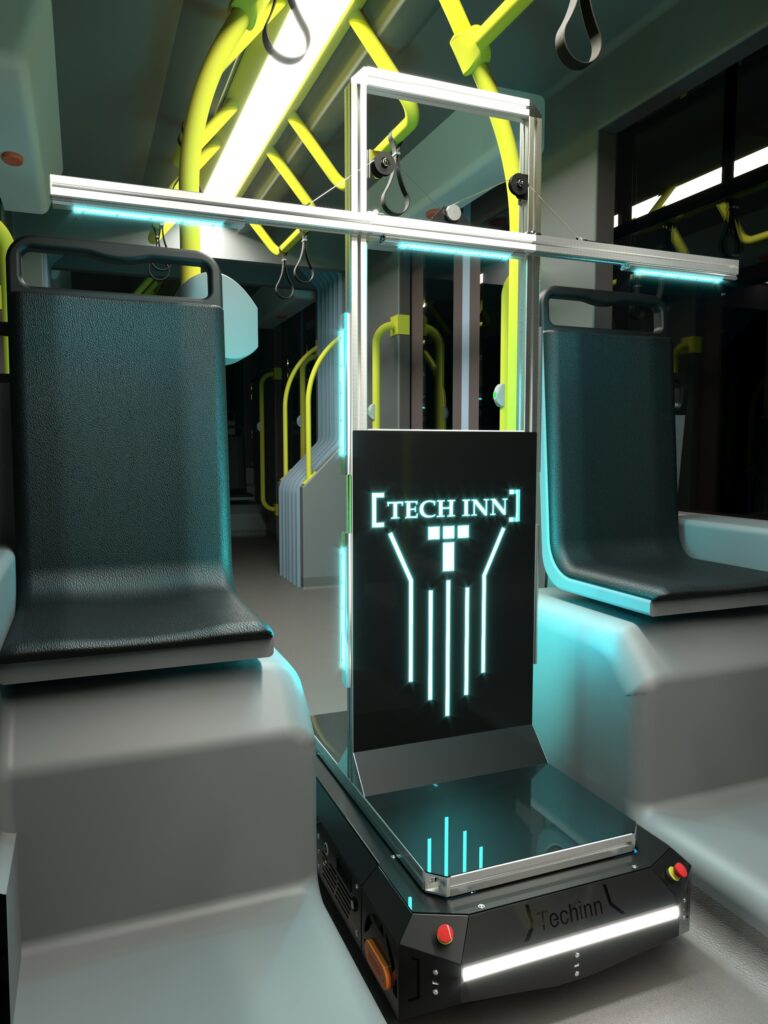

– At the exhibition, we will present a completely new concept of the TechDrive robotic platform. The platform is fully autonomous, designed to host equipment for rolling stock service in Smart Depot. It is controlled using machine vision and sensors. The robot is highly maneuverable thanks to Mecanum wheels.

This project is the future of the company; attachments for brake system cleaning and surface disinfection have already been developed for this platform.

– As I understand it, this will be a premiere? Tell us more about TechDrive.

– Yes, indeed, this will be the premiere of the TechDrive platform at InnoTrans 2024. TechDrive offers an intuitive, efficient, and cost-effective solution for autonomous and controlled transportation of heavy tools and cargo, providing management flexibility.

The versatile robotic TechDrive platform is specially designed for railway depots.

The platform includes several modules: DroneBox—a drone-based inspection system for daily monitoring. HydBox One—a device for cleaning and filling hydraulic brake systems. Disinfector—a surface disinfection system for rolling stock. SandBox—a sand filling system.

Thanks to its modular additions, the robotic platform can perform a full range of maintenance tasks for railway transport in depots.

– What else will TechInn s.r.o. showcase at InnoTrans 2024?

– In addition to TechDrive, we plan to showcase our new solutions for optimizing brake system maintenance, including the TechHydraulic Platform.

This platform allows for a complete brake system cleaning and offers automated monitoring and process management solutions.

We will also demonstrate our DBOX ONE and HYDBOX, which greatly simplify and speed up brake system and other critical vehicle component maintenance, as well as the Air disinfection system.

– TechHydraulic Platform sounds like a revolutionary solution. What issues does it help solve in tram and metro brake system maintenance?

– TechHydraulic Platform is designed to address several key challenges faced by transport companies. First, it provides complete brake fluid cleaning, which significantly improves brake system conditions and prevents premature wear.

Second, we have integrated wireless data transmission and protocol storage systems, simplifying maintenance control and analysis.

Our platform also includes portable and automated devices that reduce maintenance time and minimize the need for manual labor.

– What advantages do you see in using remote monitoring systems like TECHMON for rolling stock management?

– TECHMON provides significant advantages, including continuous monitoring and control of key rolling stock parameters in real-time.

This enables operators to promptly identify and address potential issues before they become critical. The system also supports AI for big data processing, allowing for more accurate maintenance planning and informed decision-making.

– Amid the COVID-19 pandemic, ensuring passenger safety has become a top priority. Could you please tell us about your Air disinfection system for public transport? What technologies does this system use, and where has it already been implemented?

– The Air disinfection system was developed to reduce the risk of virus and bacteria infection in passenger transport. We use ultraviolet LED (UVC) technology, which has proven effective in destroying up to 99.9% of viruses and bacteria in the air.

The system has already been successfully implemented in several cities, including Bratislava, Prague, and Cairo, where it has shown excellent results in disinfecting air in trams and metro cars.

This modular system easily integrates into various types of transport and can be installed on both new and existing vehicles.

– How do you see the future of digital transformation in the transport industry, and what trends do you consider most significant?

– The future of digital transformation in the transport industry is tied to the further adoption of Internet of Things (IoT), artificial intelligence, and automation technologies.

Key trends include the development of remote monitoring systems, improved air quality in public transport, and increased efficiency of technical maintenance.

We also see growing interest in integrating various solutions to create smart transport systems that provide enhanced safety and efficiency.

– Where are your products, such as the TechHydraulic Platform and TECHMON, already in use, and what results have been achieved?

– Our products are already actively used in several transport depots and railway enterprises. For instance, the TechHydraulic Platform has been implemented in several tram depots across Europe, where it has shown excellent results in improving brake system maintenance quality and reducing rolling stock downtime.

The TECHMON system is also used by some railway operators, significantly enhancing the monitoring and management of rolling stock technical conditions, providing more efficient and proactive maintenance.

– Do you plan to hold meetings at InnoTrans 2024? If so, what topics will be discussed, and how can potential partners schedule a meeting?

– Yes, we plan to hold several meetings at InnoTrans 2024. We will be happy to discuss our innovative solutions, such as TechDrive, TechHydraulic Platform, and remote monitoring systems, with potential partners and clients.

We are also open to discussing possible joint projects and partnerships. All interested parties can schedule a meeting with us through our website or contact us via email. We look forward to productive discussions and new opportunities for collaboration.

– What would you like to wish the participants of InnoTrans 2024 and your potential partners?

– I wish all participants of the exhibition a successful event, interesting meetings, and productive negotiations. I hope our presentation at InnoTrans 2024 will help us establish new contacts and open up opportunities for collaboration, leading to the further development of innovative solutions in the transport industry.

You can explore TechInn s.r.o.’s products at InnoTrans 2024 – Hall 7.1a, Stand 212. We invite all guests and participants of the exhibition to visit the TechInn s.r.o. stand to learn more about our innovative solutions and discuss partnership opportunities.

Contacts:

+420 608420542

contact@tech-inn.cz

https://tech-inn.cz

Railway business, industry, and technology news from Railway Supply that you may have missed:

How Smart Is Your Rail Depot? Robotic Maintenance Insights from InnoTrans

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit