Ukrainian high-speed interregional electric trains ‘Tarpan’: in 10 years of operation – 145 circumnavigations of the globe!

24.06.2024

EKr1: A Breakthrough in Domestic Engineering

On June 24, 2014, the railway stations “Darnytsia” and “Kyiv-Pasazhyrskyi” were bustling with people: officials, journalists, and passengers. Everyone wanted to embark on the maiden voyage of the domestic high-speed interregional dual-system train EKr1-001 “Tarpan.” Along with the happy passengers, it departed for Lviv on its debut journey precisely at 5:20 PM. On the same day, the second “Tarpan,” EKr1-002, set off on a trial run to Odesa. This was reported by the railway transport news portal Railway Supply, citing PJSC Kryukov Railcar Building Works (KRCBW).

On June 24, 2024, it will be 10 years since two Ukrainian interregional high-speed dual-system electric trains, EKр-1 “Tarpan,” manufactured by PJSC Kryukov Railcar Building Works (KRCBW), joined Ukrzaliznytsia. Operating in the “Intercity+” category, they have been transporting passengers and covering millions of kilometers on railway lines.

According to the “Center for Transport Strategies” portal, this achievement was among the top five most significant and notable events in Ukraine’s railway sector in 2014. Experts hailed it as a breakthrough in domestic engineering: Ukraine joined the list of 10 countries worldwide capable of designing and producing high-speed electric trains.

Ukrainian passengers gained the opportunity to travel in comfortable and safe conditions, enjoying all the modern conveniences found in similar trains around the world. Moreover, everyone—from railway technology specialists to passengers and all Ukrainians—received clear evidence that domestic transportation engineering specialists are capable of creating and producing rail technology that meets global standards in this class.

The 10th anniversary of the inaugural journey of the Ukrainian dual-system high-speed interregional electric trains “Tarpan” coincides with the 155th anniversary of the Kryukov Railway Car Building Works, the birthplace of these powerful and beautiful machines.

What have the 10 years of “Tarpan” operation shown? Firstly, they have operated on various routes such as Kyiv-Lviv, Kyiv-Odesa, Kyiv-Kryvyi Rih, Kyiv-Zaporizhzhia, Kyiv-Ternopil, Kyiv-Dnipro, and more. Each of these routes has its own infrastructure and specific characteristics that need to be known and considered during operation.

Secondly, they have demonstrated their ability to operate on the high-speed schedule of Intercity+ class trains. Notably, it was the “Tarpan” high-speed electric train from PJSC “Kryukov Railway Car Building Works” that delivered the 5-millionth passenger of the Ukrainian Railway High-Speed Company (UZSHK) to Kyiv in February 2015.

Thirdly, they have proven their operability and reliability in autumn and winter conditions, which is crucial for our climate zone.

They have shattered the stereotype that only imported technology can be advanced and modern. Feedback from passengers, received by the factory, Ukrzaliznytsia, and published in the media, on social networks, and forums, indicates that Ukrainian passengers want and can be proud of products manufactured in Ukraine. We will return to this discussion later.

History of the Creation of Ukrainian Electric Trains “Tarpan”

The history of creating domestic electric trains is dramatic and challenging.

Given the geographical location of Ukraine’s main administrative and cultural centers, the most effective type of rail passenger service is a network of daytime high-speed routes. The first stage in implementing the concept of daytime accelerated service was the launch of trains manufactured by Kryukov Railway Car Building Works (KRCBW) under the “Capital Express” brand on the Kyiv-Kharkiv route in 2002 and the Kyiv-Dnipro route in 2003. The further development of such services was envisioned with the use of modern interregional electric trains starting in 2006.

Ukrainian Railways held high-level negotiations with the leadership of ALSTOM regarding the possibility of supplying high-speed Pendolino electric trains. However, for various reasons, cooperation between “Ukrzaliznytsia” and foreign companies in this direction was discontinued during that period.

The new wave of activity came in January 2007 after Ukraine, together with Poland, won the right to host the final part of the Euro 2012 football championship. During a visit by the Ukrainian government delegation to Paris, there was an expressed desire to implement a project for the supply of rolling stock by ALSTOM (seven Pendolino trains) to facilitate high-speed transportation in Ukraine. Specialists from KRCBW actively participated in these negotiations, as our enterprise was considered a potential domestic partner for such an ambitious project. Unfortunately, once again, it was “frozen.”

Therefore, we realized the need to rely on our own strengths and experience gained from creating passenger cars and metro trains, as well as positive results from implementing accelerated passenger transportation in Ukraine.

At the initiative of KRCBW, technical requirements for interregional electric trains were developed and approved by Ukrzaliznytsia as early as 2008. We purposefully pursued the creation of motor railcars. By 2010, KRCBW was serially producing a wide range of locomotive-hauled cars, supplying them to Ukrzaliznytsia and for export. Six domestic metro trains from KRCBW were already operational in the Kyiv Metro. Trials of RIC gauge cars for international transportation continued, with restaurant cars, sleeping cars, a special car for transporting automobiles, compartment cars, couchette cars, cars with convertible furniture, and cars for interregional locomotive-hauled trains having been developed.

At the end of 2010, it became known that the Government, Ministry of Infrastructure, and Ukrzaliznytsia intended to purchase 10 interregional electric trains for the Euro 2012 football championship. On December 3, 2010, a pivotal meeting took place in the Ukrainian Cabinet of Ministers regarding the creation of a dual-system interregional electric train for the domestic railway operator. The option of acquiring electric trains from a Korean company or from the domestic manufacturer, Kriukiv Railcar Building Works (KRCBW), was under consideration. Despite assurances from KRCBW about producing the required number of trains for Euro 2012, the Prime Minister decided to purchase 10 Korean electric trains. However, he also approved the manufacture of 2 domestic trains by KRCBW, with subsequent acquisition funded by Ukrzaliznytsia.

Unfortunately, it became clear in early 2011 that these domestic trains would not be produced.

Therefore, to create and conduct all necessary testing, certification, and approval processes for the Ukrainian railways, the domestic manufacturer had to risk its own funds without any concrete guarantees of purchasing the finished product or payment terms. We accepted this challenge and began creating entirely new products for Ukraine’s machinery industry.

During this period, KRCBW also entered into a contract with UZ to create two locomotive-hauled interregional trains, which were a logical continuation of the “Capital Express” series. Eventually, the order was reduced, leaving one 9-car train set. It turned out to be remarkably successful, offering the highest level of comfort. On April 2, 2012, it commenced operations on the Kyiv-Kharkiv route.

But let’s return to the electric trains. In an incredibly tight timeframe, efforts were organized to define technical specifications for the new electric train, its life support systems, electrical equipment, chassis, and braking systems. A detailed plan was formulated for the development of design documentation, manufacturing, and testing of individual components and systems. Dozens of domestic engineering enterprises, electrical engineering firms, life support system providers, and even space industry entities were engaged in the project. Foreign specialists and companies from Poland, Germany, Austria, France, and other countries actively participated in the creation of the Ukrainian electric train. Technical challenges were addressed with the involvement of industry and academic research organizations. Thus, Kriukiv Railcar Building Works (KRCBW), together with its partners throughout 2011-2012, ambitiously brought to life the most ambitious project in its history.

I understood that our team had never faced such an extraordinarily complex task before, one that had to be completed within such tight deadlines. Yet, I knew that we were capable of achieving great things if we mobilized ourselves. I believed that our team would not let us down and that we would fulfill our commitments to the government. With this mindset, we approached our work.

At that time, Georgiy Ignatov, the Chief Designer of Social Transport and project leader for the assembly of electric trains, demonstrated crucial initiative. To expedite the assembly of the main carriages, he proposed involving specialists from the design and engineering department in the installation of systems and equipment. He organized teams of designers and workers to operate in two shifts, twelve hours each, enabling round-the-clock work. Designers led the assembly process, collaborated closely with workers, and sought optimal solutions. This approach facilitated the rapid assembly of necessary components and their immediate installation.

The carriages of the electric train, especially the main ones (essentially dual-system electric locomotives), represented not just new products but the most complex machines filled with diverse electrical equipment. It was challenging, but the team’s motto was “eyes fear, hands do!” They worked in an atmosphere of mutual support and competition, taking on responsibility and risking their effort and time without hesitation.

Soon, the first interregional high-speed dual-system electric train was ready. However, due to ongoing tests of Korean and Czech trains on the railway, our tests were delayed. They eventually commenced on July 20, 2012, on the Prydniprovska railway and proved successful. On December 13-14, 2012, an interdepartmental commission evaluated the Ukrainian electric train. It was designated as EKr1 (Kryukov’s first train), and the commission insisted on additional tests before final acceptance.

And then, more trials followed. The electric train completed three test runs on the routes Kyiv-Kharkiv, Kyiv-Donetsk, and also visited Lviv and Poltava. Throughout the testing period, it covered a total of 60,000 km. It wasn’t until April 5, 2013, following the successful testing of both EKr1 trains, that they were granted permission for regular operation, along with approval to manufacture a batch of 10 units.

However, both EKr1 trains remained idle in the new factory assembly hall, and the issue of their acquisition was unresolved… It was only after the Revolution of Dignity (a series of national-patriotic protests in Ukraine primarily against corruption, law enforcement abuses, and in support of Ukraine’s European integration) — that the new President and government of Ukraine decided to purchase and put our electric trains into service, naming them “Tarpan.” It took more than a year and two months after the favorable verdict of the interdepartmental commission (MVK) on June 17, 2014, for us to send the first train to Kyiv on June 19, the second one.

When we bid farewell to “Tarpan” on its inaugural journey, we placed the brand-new diesel train DPKr-2 alongside it at Darnytskyi railway station in the capital. Now, it and six more DPKr-3 trains, totaling seven diesel trains produced by KRCBW, are operating on Ukrzaliznytsia, transporting passengers.

In March-April 2022, amidst full-scale aggression against Ukraine, the DPKr-3 diesel trains operated multiple-unit evacuation passenger services on the Lviv-Przemyśl (Poland) route continuously for over a month and a half. They carried three times the expected number of passengers. Thus, under extreme conditions, the reliability of domestic technology was once again confirmed. We take pride in having assisted the people of Ukraine and Ukrzaliznytsia during difficult times.

Technical specifications of the high-speed interregional electric train “Tarpan”

The high-comfort dual-system electric train of the ЭКр1 series, manufactured by Kriukiv Railcar Building Works, consists of 9 carriages – two main and seven intermediate. It is equipped with 8 traction motors with a total nominal power of 4000 kW. During acceleration, the power can reach 5280 kW, ensuring high dynamic performance of the train.

The operational speed is 160 km/h (designed for 176 km/h). One of the trains, EKr1-002, was specifically designed and manufactured for speeds up to 200 km/h (220 km/h). It is equipped with appropriate bogies, braking system, and special software. We made numerous requests to conduct tests of this train at speeds up to 220 km/h, but it was futile as it requires a suitable test track. However, on our own initiative and in violation of the 2012 regulations, we managed to accelerate the EKr1-002 to 195 km/h, a fact that has been documented!

The EKr1 electric train is equipped with a crash-protection system located in the main section of the carriage. This device helps preserve the train and its passengers in emergency situations by absorbing the impact energy of collisions with obstacles, dissipating up to 2 MJ of kinetic energy.

The carriages are made of stainless steel and feature robust couplers and sealed intercar transitions. The train is equipped with a state-of-the-art climate control system, vacuum-type closed toilets, and automatic diagnostics for all systems. Progressive model bogies manufactured by KRCBW are installed, featuring pneumatic suspension, automatic anti-skid devices, and axle heating control, ensuring smooth operation and enhanced comfort levels. For the first time, a national passenger bogie has been created for speeds up to 200 km/h.

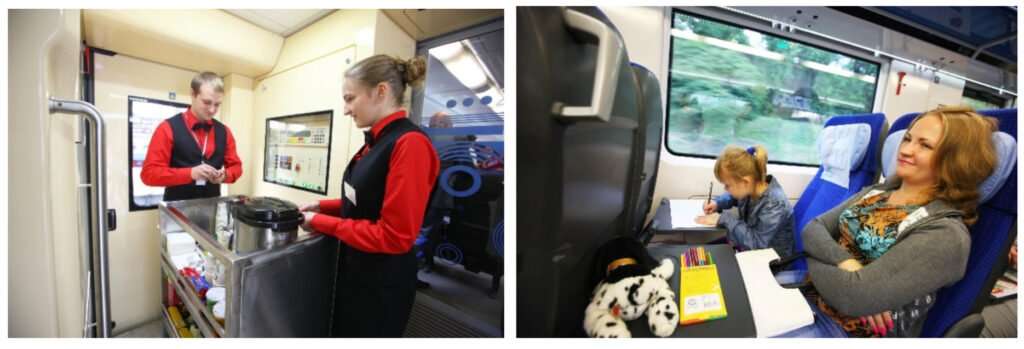

The electric train includes first, second, and tourist class carriages, capable of transporting 609 passengers, including those in wheelchairs. Comfortable temperatures are maintained year-round in all compartments, including vestibules and intercar transition zones. One of the carriages is equipped with a bar, and a catering system similar to civil aviation is implemented for passenger service.

Each carriage is equipped with its own powerful battery pack, ensuring prolonged support for equipment and safety systems during emergencies. In case of battery failure, safety systems in the carriage will be powered by an adjacent carriage, significantly enhancing the train’s resilience.

The passenger cabins are heated using an electric air-heating system, with dedicated transformers in the main carriages providing the necessary electrical power. To prevent heating failure during winter, the train design includes dual power redundancy; even if one transformer is operational, heating functions remain fully operational.

During the journey, passengers in all carriages receive information on speed, air temperature, travel time, and time to destination. High-speed internet access is available onboard the electric train. Surveillance cameras are installed in passenger cabins and vestibules. The entrance door ensures high density while featuring a safety mechanism to prevent passenger entrapment. All door operations are accompanied by voice messages for passenger guidance and safety.

Great attention has been paid to the interior of the “Tarpan” electric train. First and second-class seats feature adjustable recline and retractable cushions. Each seat in both classes is equipped with power sockets for charging mobile phones or working with laptops. Special areas for large luggage and outerwear are available in the cabins.

It’s worth noting that this high level of safety, comfort, and service equipment, meeting the best global standards in its class, was achieved 10 years ago! If the assembly and procurement of such technology had continued, it would have marked a significant advancement in high-speed transportation. Ukraine would have advanced in infrastructure development and passenger service quality!

Made in Ukraine

Our electric trains are a Ukrainian product, with localization reaching 70 percent. Over 180 partner enterprises in Ukraine and abroad were involved in their production, along with scientific and technical organizations from Kharkiv, Kyiv, Kremenchuk, and Dnipro.

Domestic trains were half as expensive as imported ones when purchased, and they are cheaper to maintain and operate. Most importantly, they are more reliable! Research conducted by the Scientific and Research Design and Technological Institute of Railway Transport (NIIKTT) of Ukrzaliznytsia, as well as by the Ukrainian State University of Science and Technology (DIIT, Dnipro), confirms that the “Tarpan” trains experience almost three times fewer failures in their systems and mechanisms compared to imports. This is despite the fact that 10 Hyundai trains were taken out of service from February to August 2014 (within six months!).

The “Tarpan” trains have successfully endured 10 years of operation in challenging autumn and winter weather conditions, largely due to the comprehensive service and timely scheduled maintenance provided by Kryukov Railcar Building Works (KRCBW).

According to current regulatory documentation and contracts with Ukrzaliznytsia, KRCBW specialists have completed the following routine repairs for each train:

- Three minor repairs (PR-3) performed every 500,000 km.

- Two major repairs (KR-1) conducted every 1,000,000 km.

Additionally, KRCBW is set to finalize a contract with Ukrainian Railways (UZ) for the major overhaul (KR-2) of two EKr1 electric trains within their premises upon reaching 3,000,000 km.

On May 24, 2024, Chief Designer for Motorwagon Rolling Stock, Ivan Kutumov, disclosed the mileage figures for our “Tarpans.” Electric train EKr-1-001 “Tarpan” has covered 2,925,803 km, while EKr-1-002 is close behind at 2,873,142 km.

It’s worth noting that the Earth’s equator measures 40,075.696 km. Thus, “Tarpan” EKr1-001 has completed 73 journeys around the world, and EKr1-002 has completed 72. Combined, they have circled the globe 145 times! The distance to the Moon is 384,000 km, and these two “Tarpans” have surpassed it more than 15 times!

Overall, the total mileage of the two “Tarpan” electric trains is approximately 6 million km. With an average route length of 500 km, this equates to 12,000 trips. Considering the maximum capacity of 609 passengers per train and the popularity of high-speed daytime transportation, each trip averages at least 500 passengers. Therefore, over the past 10 years of operation, these two “Tarpans” have transported 6 million passengers.

Passengers who have traveled multiple times in these comfortable carriages have consistently praised the “Tarpan” from KRCBW. Among the thousands of views of videos featuring the “Tarpan,” many positive reviews stand out. Under a video titled “EKr1 ‘Tarpan’ – History of the Electric Train! A Miracle from KRCBW!” one user commented: “I would deliberately choose to travel on it, even if tickets were 10% more expensive than Hyundai’s! Let’s produce more of them, export them, pay taxes into the budget, and raise the wages of those who create this beauty!” Another video reviewer wrote: “Yes! Beautiful! When I filmed its review, I walked inside from beginning to end! In some aspects, Hyundai is far behind EKr1.”

Interestingly, reviews and comments about the domestic electric train are not limited to Ukrainian; there are also numerous comments in English, French, and other languages. One foreign passenger remarked, “Beautiful train journey. Seat layout and passenger amenities are top-notch. The carriages look wider than our Indian ones.”

The creation of the “Tarpan” electric trains in Ukraine and their successful 10-year operation mark a significant milestone in assessing the capabilities of the manufacturing enterprise, its technical potential, resilience, and focus on achieving results. This achievement reflects not only the efforts of Ukrzaliznytsia and KRCBW but also the collaboration of numerous partners from supplying enterprises and scientific organizations. Together, they have navigated creative exploration, applied new engineering solutions, and accepted certain risks in the pursuit of advancing Ukraine’s economy and engineering industry.

It is disappointing, however, that over the past decade, Ukrzaliznytsia has only acquired two high-speed EKr1 electric trains. Unfortunately, the situation has not improved for domestic manufacturers. We eagerly await joint projects with Ukrzaliznytsia aimed at deep localization efforts in the procurement of imported trains. Once again, we emphasize the urgent need to change attitudes towards Ukrainian equipment manufacturers!

The successful 10 years of operation of the EKr1 “Tarpan” allow us to assert that prioritizing Ukrainian manufacturers of high-speed interregional trains should be the unequivocal choice today and in the future. This sentiment applies not only to the “Tarpan” but also to other products of KRCBW and Ukrainian mechanical engineering as a whole.

Another stage in the implementation of high-speed passenger transportation with significant reductions in travel time on “Intercity+” routes requires the use of rolling stock with operational speeds of 200 km/h and above, along with improvements to railway infrastructure, track superstructure, and electrification systems, including dedicated lines for high-speed passenger traffic. Domestic engineering, with real state support and the involvement of PJSC “Ukrzaliznytsia,” is preparing to consider the possibility of creating such rolling stock. Given the necessity of substantial and long-term financial investments not only in new rolling stock but also in infrastructure, it is strongly hoped that Ukraine’s potential will be mobilized to the fullest extent, creating new jobs, similar to the initiatives in France, Germany, and Great Britain, which had a multiplier effect on the economies of those states.

Considering that Ukraine’s future lies within a Unified Europe, undoubtedly, after the war concludes, the question of broader and comprehensive integration, including Ukraine’s railway infrastructure into the unified European railway network, will become increasingly acute. Intensive construction of the 1435 mm gauge railway network along key routes like Kyiv-Lviv, Kyiv-Kharkiv, Kyiv-Odesa, and Kyiv-Donetsk is inevitable, thereby opening Ukraine’s market to European high-speed rolling stock. However, this will take years, even decades, while Ukrainian citizens desire comfortable and rapid railway travel today.

The Kryukov Railcar Building Works (KRCBW) can already offer Ukrainian railway operators (and soon, private operators) modern high-speed rolling stock, proven over time and appreciated by passengers. KRCBW specialists are ready to tackle new challenges. In recent years, we have been actively developing freight rolling stock for European railways on the 1435 mm gauge.

Our experience, persistence, competence, and diligence cannot go unnoticed by leading global manufacturers of products for high-speed and very high-speed passenger transportation. In a partnership environment, mutually acceptable and beneficial economic and technical contacts will be established, uniting domestic potential, European technologies, and the latest competencies into a completely new innovative transport system for Ukraine. We are confident in this!

Congratulations to everyone involved in the creation and operation of the “Tarpan.” I believe that many more than a million satisfied passengers will be transported by these electric trains, characterized by their spirit and pursuit of freedom!

Vladimir Prykhodko, Chairman of the Supervisory Board of PJSC “Kryukov Railcar Building Works” laureate of the State Prize of Ukraine, member of the Presidium of the Federation of Employers of Ukraine, candidate of technical sciences.

Rail business, industry, and railway technology news from Railway Supply that you might have missed:

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit