The robot Spot is already inspecting the wheelset axles of DB Cargo’s freight cars

22.04.2024

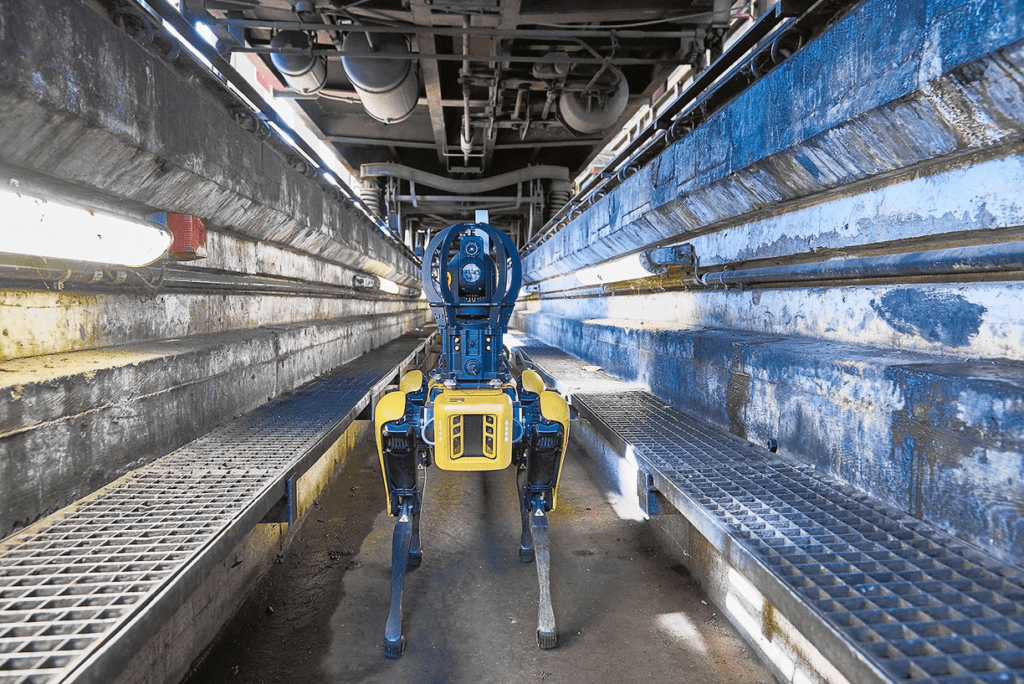

At the wagon maintenance depot in Mainz-Bischofsheim, they are testing the quadruped robot Spot, which has been equipped with equipment for identifying freight cars and determining their locations in the depot’s tracks, as well as for inspecting the condition of the wheelset axles, this is reported by the railway transport news portal Railway Supply.

Based on the results of the testing, the operator DB Cargo, a part of Germany’s railway (DB), will decide on the use of such robots in its other depots.

Wabtec and Australian Rail Track (ARTC) have signed an agreement for collaboration

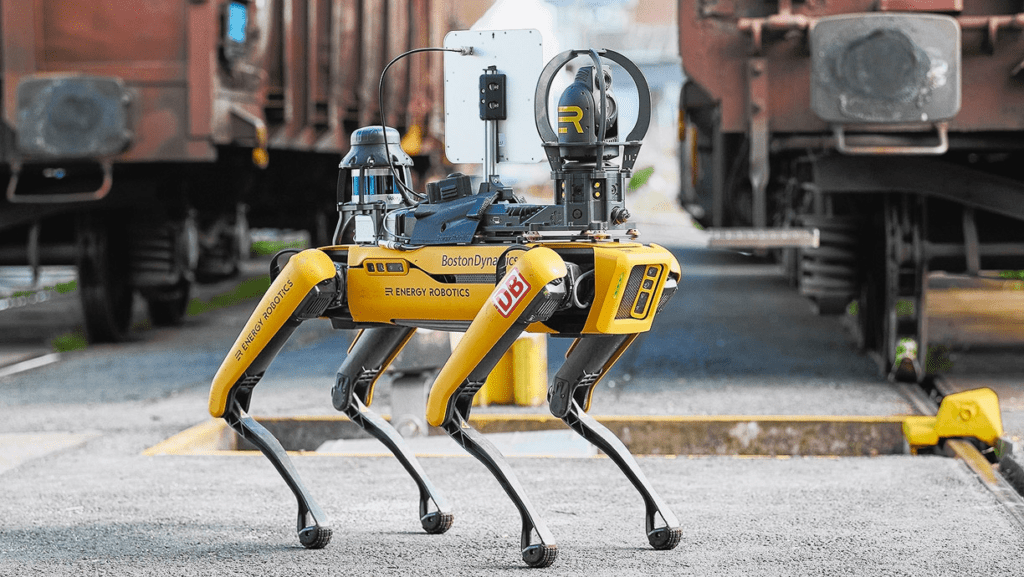

The Spot robot, produced by the American company Boston Dynamics, is capable of moving independently along tracks and descending stairs into the depot’s inspection pits.

It is equipped with cameras, sensors, and artificial intelligence tools that allow it to independently identify wagons and visually inspect them to detect possible defects.

An RFID tag reader is used for wagon identification.

DB Cargo expects that the use of robots will free up workers from routine activities, reduce labor costs, and decrease the cost and duration of wagon maintenance.

In the future, the operator intends to expand the robots’ functions so they can recognize other freight car defects.

The Spot robot weighs 25 kg, is 84 cm tall, and has a speed of up to 6 km/h. The applied software for it was developed by the German startup Energy Robotics according to DB’s technical specifications.

In March 2024, testing of the Spot robot began on the urban railway in Munich, where it patrols the train park and, upon detecting unauthorized individuals, transmits information to DB’s security service staff.

This step allows for expanding the use of Spot robots not only in depots but also in other sections of railway infrastructure.

The use of robots in the railway industry has the potential to significantly improve the efficiency and safety of train servicing.

Robots can operate in conditions inaccessible to humans, conduct more precise and systematic inspections, and reduce wagon downtime by promptly detecting and rectifying defects.

Thus, the integration of the Spot robot into the operations of the railway operator DB Cargo opens up new perspectives in the field of automation and enhances the efficiency of freight car maintenance.

Photo: DB

Rail business, industry, and railway technology news from Railway Supply that you might have missed:

Knorr-Bremse acquires part of Alstom’s business in railway automation and telemechanics

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit