The DMJ-4-B machine for rough grinding of welded joints of steel rails

The DMJ-4-B machine for rough grinding of welded joints of steel rails is used for automatic grinding of the upper part and the base of the rail head at the welded joint locations after rail welding.

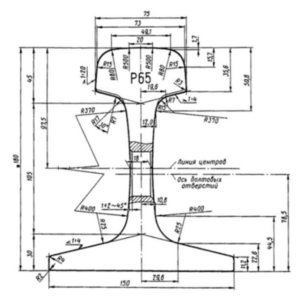

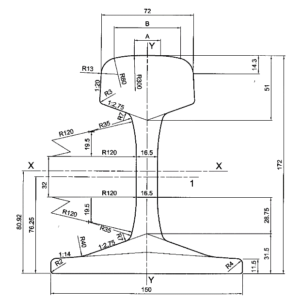

It is capable of automatically grinding welded joints of steel rails weighing 60 kg/m, 43 kg/m, 50 kg/m, and 75 kg/m.

Grinding of one rail head is completed in 5 minutes.

The equipment provides advanced processing methods: by changing the traditional manual process of grinding welded seams by copying to automatic grinding with a grinding wheel, it reduces labor intensity and saves labor costs, significantly increases production efficiency and the quality of welded seams, and reduces environmental pollution.

The machine for rough grinding of welded joints of steel rails is equipment used for processing welded connections between steel rails on railway tracks.

It is designed to remove irregularities, defects, and excess weld metal to ensure smoother and safer passage of trains.

This process helps improve the quality of tracks and enhance train movement safety.