Sleepers Made of Sulphur Concrete: A Sustainable Railway Solution

07.10.2024

At InnoTrans 2024, THIOTRACK showcased its innovative sleepers made of sulphur concrete, designed to address the growing demand for sustainable railway infrastructure, this is reported by the railway transport news portal Railway Supply.

These sleepers reduce the carbon footprint by 50%, making them a top choice for environmentally conscious railway projects. In addition to their eco-friendly design, sleepers made of sulphur concrete offer 100% recyclability, allowing companies to reuse materials efficiently without compromising on performance.

Greenbrier Tank for Safe and Efficient CO2 Transportation

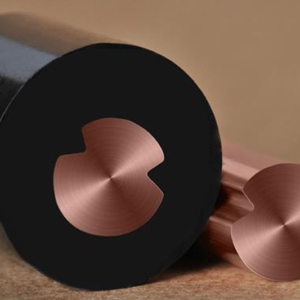

THIOTRACK has revolutionized the manufacturing process of these sleepers by eliminating the need for water and cement. Instead, sulfur replaces these traditional materials, significantly reducing resource consumption.

This process not only lowers production costs but also minimizes environmental impact. As a result, railway companies seeking green solutions can confidently invest in sleepers made of sulphur concrete to meet sustainability goals without sacrificing durability.

Environmental Advantages of Sleepers Made of Sulphur Concrete

One of the key benefits of sleepers made of sulphur concrete is their recyclability. By heating them to 135°C, sulfur separates from steel reinforcements, allowing nearly all materials to be reused.

This approach addresses the pressing issue of raw material shortages and provides a sustainable solution for the railway industry. Unlike traditional concrete sleepers, sleepers made of sulphur concrete do not contain harmful chemicals, ensuring a safe and eco-friendly option for railway tracks.

Their high durability also reduces maintenance costs, as they require fewer replacements. By choosing sleepers made of sulphur concrete, railway operators can lower their long-term operational costs while contributing to environmental sustainability.

Furthermore, these sleepers comply with European safety and performance standards, making them a reliable choice for any railway system. With the growing global focus on reducing carbon emissions and promoting sustainable infrastructure, sleepers made of sulphur concrete are an essential tool for modern railway development.

Sleepers Made of Sulphur Concrete: A New Era for Global Railways

As railway infrastructure continues to expand worldwide, sleepers made of sulphur concrete play an increasingly vital role in creating eco-friendly transportation networks. Their ability to reduce the need for water and cement significantly lowers the environmental footprint of railway construction projects.

THIOTRACK’s innovative sleepers meet the increasing demand for sustainable building materials while offering the long-term benefits of cost savings and performance efficiency.

In addition to their environmental advantages, sleepers made of sulphur concrete solve a critical issue in the railway industry—raw material shortages. By recycling nearly 100% of their components, these sleepers ensure that future railway projects can be built with minimal environmental impact. This innovation sets the stage for a more sustainable and resource-efficient approach to railway construction.

In conclusion, sleepers made of sulphur concrete from THIOTRACK represent a groundbreaking solution for the future of railway infrastructure. Their reduced carbon footprint, recyclability, and compliance with stringent industry standards make them a reliable and eco-friendly choice for railway operators.

As demand for sustainable solutions grows, these sleepers will play a pivotal role in shaping the next generation of railway systems worldwide.

Rail business, industry, and railway technology news from Railway Supply that you might have missed:

Railway Digitalization in Azerbaijan Boosts Efficiency and Safety

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit