Pendolino Train Modernization: Enhanced Technology and Comfort for Passengers

23.12.2024

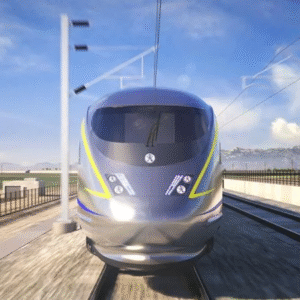

The French company Alstom showcased a video demonstrating the inspection process for Pendolino trains. The overhaul took place in the United Kingdom, where one train received major upgrades. This was reported by the railway transport news portal Railway Supply.

Pendolino Train Tilting Technology

Pendolino trains can reach speeds of 200 km/h and tilt up to 8 degrees. This feature helps them navigate curves 20% faster than standard trains, improving efficiency and performance.

Don’t miss…Senate Confirms New Members to Amtrak’s Board for Infrastructure Growth

The Italian company Fiat Ferroviaria originally developed this tilting technology in the 1970s. Alstom acquired the company in 2000 and introduced further technological advancements to improve reliability.

Similar systems operate in Spanish Talgo models and Japanese high-speed trains. The tilting mechanism reduces stress on tracks and enhances passenger comfort, ensuring a smoother travel experience.

Pendolino Train Overhaul and Modernization

The fleet of 56 Pendolino trains, classified as Class 390 in the UK, received upgrades. The refurbishment was completed in June at a technical service center located in Widnes, England.

First Trenitalia signed a contract for these upgrades in 2020 at a total cost of £117 million (€137.3 million). The project included interior enhancements, seating upgrades, and undercarriage repairs.

The modernization process improved traction motors, replaced key components, and added better lighting and air conditioning systems. These updates extend service life and increase operational efficiency.

Alstom highlighted the importance of frequent updates to maintain reliability and performance standards. The upgraded trains balance technological innovation with high-speed capabilities for modern rail transport.

Pendolino trains support sustainable travel by promoting rail use on busy routes with lower emissions. They combine efficiency and comfort, meeting today’s standards for passenger safety and satisfaction.

Alstom released a video showing the refurbishment process and testing procedures. The footage highlights technical improvements and showcases the upgraded train systems in action.

The trains feature new seating arrangements, energy-efficient lighting, and advanced ventilation systems. These updates ensure greater comfort and align with modern safety regulations.

Company officials emphasized that the modernization program would keep the trains competitive in the transportation sector. Alstom remains focused on innovations to improve service quality and passenger experience.

Modernization programs contribute to infrastructure development and promote eco-friendly transportation solutions across Europe. They encourage rail travel, helping reduce carbon emissions and environmental impact.

First Trenitalia stressed the importance of its partnership with Alstom in completing this project. Both companies plan to implement more advanced technologies for sustainable transport solutions.

Alstom intends to expand testing and modernization programs for its trains in the future. Investments in rail technology solidify the company’s role as an industry leader in transportation.

News on railway transport, industry, and railway technologies from Railway Supply that you might have missed:

Don’t miss…Railway Reform: Greece Modernizes Its Rail Infrastructure and Safety Standards

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit