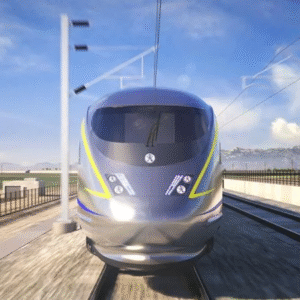

Mumbai-Ahmedabad Bullet Train: A High-Speed Revolution in Rail Travel

07.12.2024

Effective train maintenance is vital for high-speed rail functionality and passenger safety. Surat’s maintenance depot spans 38 hectares, making it the smallest but essential for daily inspections. This was reported by the railway transport news portal Railway Supply.

Thane Depot, covering 58 hectares, manages regular upkeep, repairs, and inspections. Sabarmati Depot—the largest at 82 hectares—hosts facilities for advanced train servicing, ensuring sustainable, long-term reliability.

Thane and Surat depots focus on daily tasks like routine inspections, maintenance, and minor repairs. Sabarmati specializes in advanced services, including bogie overhauls and comprehensive train examinations, supporting long-term train performance. This three-tiered system guarantees efficient upkeep and uninterrupted service.

Sustainability Embedded in Maintenance Practices

Sustainability underpins every aspect of the MAHSR project’s operations. Maintenance depots integrate eco-friendly technologies such as solar panels, ultra-efficient water systems, and wastewater treatment facilities. Rainwater harvesting systems complement this approach, reducing environmental footprints while supporting sustainable operations.

Don’t miss…Cardiff Crossrail: The First Step Towards a Modern Transport Network in Cardiff

Energy-efficient practices ensure minimized resource consumption, aligning with India’s green development goals. These environmentally conscious initiatives also cut operational costs, enhancing the project’s overall efficiency.

Advanced Monitoring for Infrastructure Performance

Monitoring systems employing cutting-edge technology ensure the safety and efficiency of the MAHSR network. Track conditions, power systems, and telecommunication networks are inspected with specialized equipment, enabling proactive maintenance. These tools provide real-time data, allowing issues to be swiftly addressed.

Inspection tools are either onboard operational passenger trains or specialized inspection trains. Traveling at high operational speeds, they identify potential problems promptly, preventing service disruptions and maintaining infrastructure integrity. Such innovations highlight the project’s focus on performance and reliability.

Commitment to Seamless High-Speed Travel

The comprehensive maintenance plan showcases the MAHSR project’s commitment to revolutionizing rail travel. Strategic depot locations and advanced technologies ensure seamless operations. The emphasis on eco-conscious solutions and real-time monitoring demonstrates a forward-thinking approach.

As India’s first bullet train project, the MAHSR sets benchmarks for sustainable high-speed rail. With meticulous planning and advanced technology integration, the system promises a new era of efficient, safe, and reliable rail travel across India.

Source, photo: www.financialexpress.com

News on railway transport, industry, and railway technologies from Railway Supply that you might have missed:

Don’t miss…Cardiff Crossrail: The First Step Towards a Modern Transport Network in Cardiff

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit