Modernization of the 2TE10M Locomotive

MLRP completed a comprehensive modernization of the 2TE10M locomotive

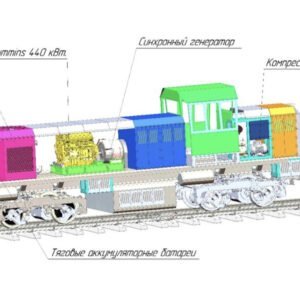

MLRP completed an extensive modernization of the 2TE10M locomotive for PJSC “ArcelorMittal Kryvyi Rih” in 2019. The following works were carried out on the locomotives:

1. Installation of a modern 8DZC diesel engine (AVS, Belgium) with a power of 2000 kW and a maintenance interval of up to 70,000 motor hours until the next major overhaul.

2. Installation of an AC traction unit A723U2 (“GP Electrotjazhmash”, Ukraine).

3. Installation of a rectifier unit on the locomotive.

4. Installation of a rotor-vane compressor unit with electric drive type AKL-6 (MTRZ, Ukraine/Mattei, Italy) with a maintenance interval of up to 100,000 motor hours.

5. Installation of axial fans for cooling the diesel working fluid.

6. Installation of centrifugal fans for cooling traction electric motors, traction unit, and rectifier unit.

7. Installation of a microprocessor control system for the locomotive.

8. Implementation of a microprocessor diagnostic complex for all locomotive systems with remote access capability.

9. Installation of the “Delta SU-GPS” vehicle control system.

10. Installation of the “Vector” electronic speedometer.

11. Installation of a video monitoring system.

12. Enhancement of crew comfort through the installation of a climate control system, anti-vibration seats, refrigerator, and microwave.

After the completion of the modernization works, the 2TE10M locomotive was put into operation on December 24, 2019. During the operational period of the modernized 2TE10M locomotive, the following economic indicators were achieved:

- Fuel consumption reduced by 38%.

- Oil consumption reduced by 80%.

- Maintenance and repair costs reduced by 50%.

- Continuous traction force increased by 15%.