Modernization of locomotives of the TEM-2 (TEM-1) series

Implementation of modernization for locomotives of the TEM-2 (TEM-1) series

During the modernization of locomotives of the TEM-2 (TEM-1) series, the specialists of MLRP perform the following works:

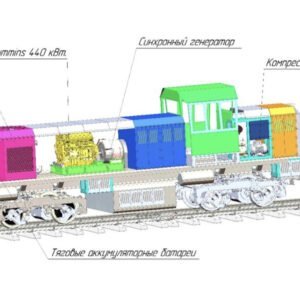

- Installation of a Cummins QST30L2 engine with a power of 882 kW (manufactured in the USA).

- Installation of a combined alternating current traction unit A735 (traction generator and auxiliary generator).

- Mounting of the rectifier unit.

- Installation of cooling fans for the traction electric drive with asynchronous electric drive.

- Installation of main diesel cooling fans with AO10 type electric drive.

- Installation of a microprocessor control system for the locomotive.

- Installation of a rotary-vane compressor type AKL-4.5 with electric drive (service life of 100 thousand motor hours).

- Overhaul of traction electric motors ED118A.

- Installation of a video surveillance system (industrial-grade with high vandalism protection) for the track area in both directions and inside the locomotive with data archiving.

- Installation of an automatic fire extinguishing system.

- Installation of an electronic speedometer Vector with a speed control system, pressure control in the brake and feed lines, power control with data archiving.

- Installation of LED projectors, buffer lights, undercarriage lighting, cabin, and engine room lighting.

- Installation of air conditioning, household refrigerator, anti-vibration seats, microwave.

- Overhaul of bogies, wheelsets, and other equipment.

- Warranty is provided for the modernized locomotive equipment for 18 months from the date of signing the completion certificate.

- A comprehensive set of works to extend the locomotive’s service life to 15 years.

The expected economic impact of modernizing the TEM-2 locomotive, according to the technical specifications of MLRP, includes:

- A 20% reduction in fuel consumption.

- An 80% reduction in oil consumption.

- A 50% reduction in maintenance and overhaul costs.

- A 10% increase in the speed and tractive effort of continuous operation.

The duration of the modernization work for the TEM-2 series locomotive is 250 calendar days. MLRP offers services for the maintenance of modernized locomotives during the warranty and post-warranty periods, and also has the capability to supply spare parts.