Future Track Maintenance Technologies: How Plasser & Theurer Sees the Future?

03.07.2024

In a rapidly changing world and increasing demands on railway infrastructure, Plasser & Theurer will present its innovative solutions at InnoTrans 2024 under the slogan «Future Track Technologies – Now», this is reported by the railway transport news portal Railway Supply.

The central questions the company will address include: How can we quickly and sustainably respond to issues caused by climate change? How can we increase the economic efficiency of track construction and maintenance? And how can we tackle the shortage of skilled workers?

Sustainable Development and Ecology

In light of climate change and global warming, Plasser & Theurer focuses on reducing emissions and operational costs.

CRRC Introduces “Yiqun”: A New Smart High-Speed Train for Future Cities

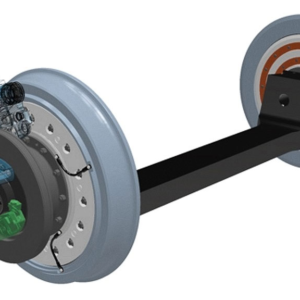

One of the key solutions is hybrid drive system machines, which not only reduce the carbon footprint but also help conserve resources.

These approaches are becoming increasingly relevant in the quest to create a more sustainable and environmentally friendly railway infrastructure.

Increasing Economic Efficiency

Economic efficiency is another important aspect that Plasser & Theurer focuses on.

Thanks to the latest equipment and the digitalization of maintenance processes, the company has achieved high speed and precision with modern technologies for railway track work.

One example of innovation is the TampingAssistant, which uses artificial intelligence to automatically position, adjust, and control tamping devices.

The operator only needs to confirm the system’s suggestions and monitor the process, allowing even inexperienced operators to achieve high-quality tamping results.

Additional solutions such as TampingControl and TampingReport provide real-time data on the quality and process of tamping and ensure digital documentation, optimizing the work process.

Solving the Workforce Issue

The shortage of skilled workers is a pressing issue in many industries, and the railway sector is no exception. Plasser & Theurer offers several solutions to this problem.

One is creating more attractive workplaces on their machines. For example, the E3 model offers comfortable crew quarters and cabins with digital control.

Another approach is process automation, which reduces the number of personnel required. For training new operators and retraining specialists, simulators are used, allowing them to practice machine operation in a safe environment.

This accelerates the adaptation process and enables new employees to start working more quickly.

Plasser & Theurer will showcase innovative solutions aimed at sustainable development, increasing economic efficiency, and addressing workforce issues at InnoTrans 2024.

By implementing new technologies and innovative approaches, the company not only responds to current challenges but also paves the way for the future of railway construction and maintenance.

Photo: Plasser & Theurer

Rail business, industry, and railway technology news from Railway Supply that you might have missed:

The growth of railway equipment production in Kazakhstan

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit