3D Printing of Railway Components

10.09.2023

ÖBB Train Tech, a business of Austrian Federal Railways, turned to Chromatic to explore the possibility of using 3D printing for replacement components, as reported by the railway portal Railway Supply.

Facing the need to replace outdated components used to reduce vibration and prevent dust and moisture ingress in their train cars, ÖBB Train Tech collaborated with Chromatic.

Export of a Batch of Hopper Cars to Kazakhstan

Prototypes were created, leading to an order for 130 gaskets, bellows, valve covers, and other spare parts.

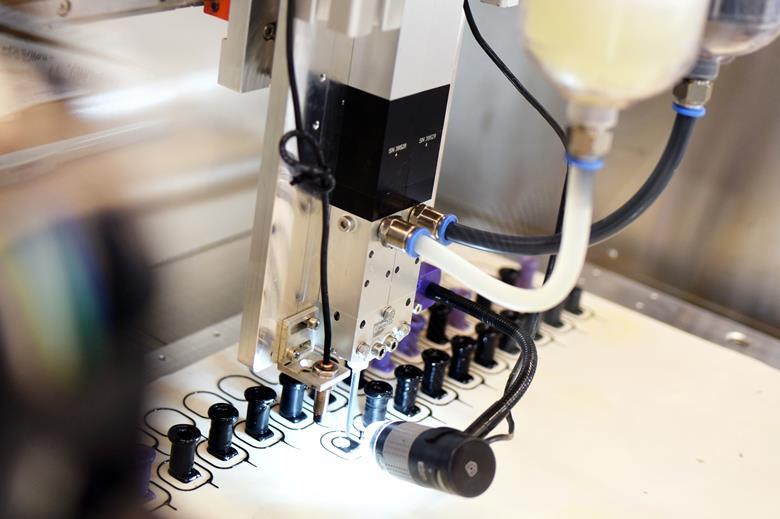

These components were 3D printed using thermoreactive polyurethane on Chromatic’s reactive extrusion platform, Chromatic RX-AM.

The bearing bushes have dense solid walls, 15mm thick, offering the same 3D strength and compression resistance as traditionally molded parts.

With ÖBB showcasing the use of their 3D materials in railway applications, Chromatic anticipates that customers in demanding transportation, aerospace, industrial, and defense sectors will trust their printing products and technology.

News in railway transportation you might have missed:

The average age of Kazakhstan Temir Zholy’s (KTZ) passenger wagon fleet has decreased.

Find the latest news of the railway industry in Eastern Europe, the former Soviet Union and the rest of the world on our page on Facebook, Twitter, LinkedIn, read Railway Supply magazine online.Place your ads on webportal and in Railway Supply magazine. Detailed information is in Railway Supply media kit